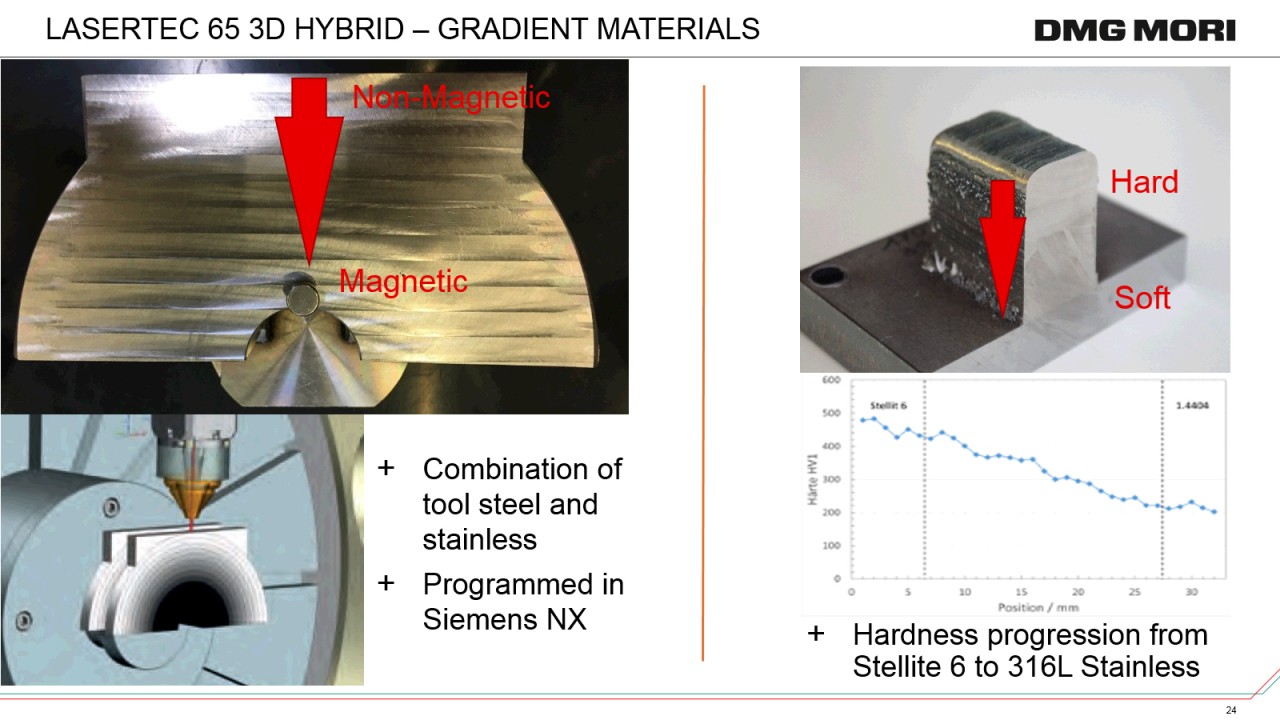

Gradient Materials on the DMG MORI Lasertec 65 3D hybrid

One of the reactions I had to my last article about multi-material using LMD was, "That is good, but what about gradient materials?". The Lasertec 65 3D hybrid machine we develop and sell does gradient materials as well, of course.

We have individual CNC control of each of the two powder hoppers. We have a clever powder mixer that comes after the hoppers. The powder mixer feeds our co-axial nozzle with powder and inert gas. The programming is done using our exclusively developed Siemens NX Hybrid CAM routines. This allows the programmer to decide not only from where to where shall be graded, but also the ratio between the two materials.

This opens up some new ways to control material properties. Magnetic to non-magnetic. Hard to soft. Controlled corrosion resistance. Gradients of thermal expansion properties. Plus, I am sure, many more possibilities that we have not yet thought of.

If you want to learn more about what the Lasertec 65 3D hybrid can do, and discuss these possibilities with me, then I look forward to seeing you at the EMO in Hannover in September.

Technical Manager

4yHello. It is very interesting but difficult to understand the process used for mixing the powders. For me, it is more obvious with DED than SLM. So, I will be happy to receive more details on your process and materials mixable. Thanks in advance.