CU1905

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

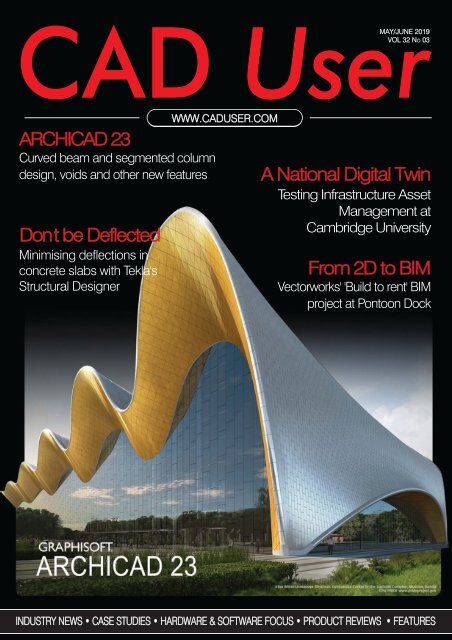

CAD User<br />

MAY/JUNE 2019<br />

VOL 32 NO 03<br />

ARCHICAD 23<br />

Curved beam and segmented column<br />

design, voids and other new features.<br />

Don't be Deflected<br />

Minimising deflections in<br />

concrete slabs with Tekla's<br />

Structural Designer<br />

WWW.CADUSER.COM<br />

A National Digital Twin<br />

Testing Infrastructure Asset<br />

Management at<br />

Cambridge University<br />

From 2D to BIM<br />

Vectorworks' 'Build to rent' BIM<br />

project at Pontoon Dock<br />

INDUSTRY NEWS • CASE STUDIES • HARDWARE & SOFTWARE FOCUS • PRODUCT REVIEWS • FEATURES

BIM Product of the Year<br />

ARCHICAD 2322 delivers delivers a quantum design leap tool in<br />

BIM improvements performance by and speeding also up introduces everyday<br />

design enhanced and editing design processes workflow and processes. ensures<br />

uninterrupted These represent workflows significant for performance<br />

the most<br />

frequently improvements used tasks. With well brand-new as productivity tools to<br />

increase enhancements modelling to accuracy, its core enable design fast processes editing<br />

and as well streamline as to multidisciplinary error-free, interdisciplinary<br />

collaborative<br />

design workflows. coordination.<br />

For further information on ARCHICAD 22<br />

To see the new ARCHICAD 23 contact<br />

contact GRAPHISOFT at graphisoft.com or call<br />

GRAPHISOFT at graphisoft.com or call<br />

01895 527590.<br />

University Library Freiburg, Germany, DEGELO ARCHITEKTEN, www.degelo.net, Photo © Barbara Bühler<br />

Irina Viner-Usmanova Rhythmic Gymnastics Center in the Luzhniki Complex, Moscow, Russia - CPU PRIDE www.prideproject.pro

CONTENTS<br />

MAY/JUNE 2019<br />

CONTENTS<br />

A NATIONAL DIGITAL TWIN 10<br />

A dynamic digital twin was created at<br />

Cambridge University's Institute for<br />

Manufacturing to test the challenges and<br />

issues associated with developing a digital<br />

model of infrastructure assets<br />

FROM 2D TO BIM 16<br />

A new 'Build to Rent' development at Pontoon<br />

Dock on the DLR provides a perfect illustration<br />

of the way processes are involved in a typical<br />

BIM project using Vectorworks software<br />

throughout<br />

ARCHICAD 23 20<br />

The latest version of Graphisoft's flagship<br />

architectural design application, ARCHICAD 23,<br />

introduces some interesting tools in Beam and<br />

Column design, and Void and Recess creation<br />

INTELLIGENT COMMUNITIES 26<br />

IES has launched new cutting-edge technology<br />

that connects distributed energy networks,<br />

renewables, master plans, building design,<br />

operation and retrofit, with the aim of building<br />

Intelligent, and well-informed, communities<br />

NEWS................................................INDUSTRY NEWS....................................................................................................6<br />

• SMART UPDATES FOR 3D REPO • EPIC GAMES ACQUIRES TWINMOTION<br />

CASE STUDY....................................SURFACING UPGRADE.........................................................................................14<br />

• TOPPESFIELD EXPLAINS THE BENEFITS THAT IMPLEMENTING RE-FLOW HAS PROVIDED ON AND OFFSITE<br />

SOFTWARE FOCUS.........................POWERPROJECT XV...........................................................................................18<br />

• MARK DIXON AT ELECOSOFT TALKS US THROUGH THE LATEST ITERATION OF POWERPROJECT<br />

TECHNOLOGY FOCUS....................DON’T BE DEFLECTED......................................................................................22<br />

• CALCULATING SLAB DEFLECTIONS WITH TEKLA STRUCTURAL DESIGNER<br />

SOFTWARE FOCUS.........................SETTING THE STAGE FOR INNOVATION.........................................................24<br />

• CREATING A UNIFIED DEFINITION FOR THE EXCHANGE OF DATA FOR THE OPERATION OF INTELLIGENT LUMINARIES<br />

TECHNOLOGY FOCUS....................GOING MODULAR..............................................................................................28<br />

• KENNY INGRAM OF IFS MAKES SOME INTERESTING PREDICTION ABOUT FUTURE CONSTRUCTION TRENDS<br />

SOFTWARE REVIEW........................MYCONSOLE.......................................................................................................30<br />

• MYCONSOLE CAN HELP YOU MAKE BUSINESS CRITICAL DECISIONS FASTER WHEN IT COMES TO WINNING TENDERS<br />

TRAINING MAP.................................AUTODESK TRAINING.......................................................................................32<br />

• YOUR GUIDE TO AUTODESK TRAINING<br />

MASTERCLASS................................Q & As WITH EASYBUILD..................................................................................34<br />

• EASYBUILD'S CONSTRUCTION SOFTWARE PLATFORM FORMS THE BASIS OF OUR NEW Q & A SERIES<br />

May/June 2019 3

COMMENT<br />

Editor:<br />

David Chadwick<br />

(cad.user@btc.co.uk)<br />

News Editor:<br />

Mark Lyward<br />

(mark.lyward@btc.co.uk)<br />

Advertising Sales:<br />

Josh Boulton<br />

(josh.boulton@btc.co.uk)<br />

Production Manager:<br />

Abby Penn<br />

(abby.penn@btc.co.uk)<br />

Design/Layout:<br />

Ian Collis<br />

ian.collis@btc.co.uk<br />

Circulation/Subscriptions:<br />

Christina Willis<br />

(christina.willis@btc.co.uk)<br />

Publisher:<br />

John Jageurs<br />

john.jageurs@btc.co.uk<br />

Published by Barrow &<br />

Thompkins Connexion Ltd.<br />

35 Station Square, Petts Wood,<br />

Kent BR5 1LZ<br />

Tel: +44 (0) 1689 616 000<br />

Fax: +44 (0) 1689 82 66 22<br />

SUBSCRIPTIONS:<br />

UK £35/year, £60/two years,<br />

£80/three years;<br />

Europe:<br />

£48/year, £85 two years,<br />

£127/three years;<br />

R.O.W. £62/year<br />

£115/two years, £168/three years.<br />

Single copies can be bought for £8.50<br />

(includes postage & packaging).<br />

Published 6 times a year.<br />

© 2019 Barrow & Thompkins<br />

Connexion Ltd.<br />

All rights reserved.<br />

No part of the magazine may be<br />

reproduced, without prior consent<br />

in writing, from the publisher<br />

For more magazines from BTC, please visit:<br />

www.btc.co.uk<br />

Articles published reflect the opinions of<br />

the authors and are not necessarily those<br />

of the publisher or his employees. While<br />

every reasonable effort is made to ensure<br />

that the contents of editorial and advertising<br />

are accurate, no responsibility can be<br />

accepted by the publisher for errors, misrepresentations<br />

or any resulting effects<br />

Comment<br />

Attaining level 42?<br />

by David Chadwick<br />

The correlation of concepts in IT is a<br />

fascinating subject in its own right,<br />

and the very latest, exemplified by the<br />

two key players in the industry - Bentley and<br />

Autodesk - focuses on future trends within<br />

the industry. Bentley's recent Future of<br />

Infrastructure Symposium was closely<br />

followed by Autodesk's release of its white<br />

paper entitled The Future of Construction.<br />

In both cases the technologies that are<br />

dominating the construction industry were<br />

presented with a view about the way each<br />

of the industries is changing.<br />

The principal themes demonstrated the<br />

use of ContextCapture, virtual and<br />

augmented realities, artificial intelligence<br />

and machine learning, and how they are<br />

becoming integrated within the design,<br />

construction and operation of buildings and<br />

infrastructure. The subplot, is of course, the<br />

development of the Digital Twin concept -<br />

the integration of all technologies involved<br />

to create a digital copy of a project that<br />

mirrors the physical entity - linked bilaterally<br />

by structural surveys, sensors, engineering<br />

changes, maintenance schedules and<br />

anything else that involves the structure<br />

during its projected lifespan.<br />

It's all part of Industry 4.0, the fourth<br />

evolutionary stage of man and science. Its<br />

essence is the integration of technology<br />

within any complex process from the above<br />

to manufacturing, facilities management<br />

within the food and drinks industry and, I<br />

would suggest, the basis of a modern<br />

healthcare system, which could do away<br />

with the voluminous sheaves of notes that<br />

accompany anyone of a certain age<br />

through the NHS.<br />

At the Bentley Symposium we were<br />

shocked out of our complacency by the<br />

brief presentation by Keith Clarke, Chair of<br />

UK Future Cities Catapult, who pointed out<br />

that over the next 50 years or so population<br />

increases, primarily in the Third World, are<br />

going to consist of huge numbers of people<br />

aspiring to become 'middle class'.<br />

Assuming we have cracked the most<br />

critical issues of feeding and watering such<br />

vast increases in population, modern<br />

communication facilities and social media<br />

present an achievable lifestyle of a similar<br />

quality to that enjoyed by more advanced<br />

countries. To satisfy that demand, Keith<br />

said, would require the construction of<br />

another half a dozen Europe's on the<br />

African and other Third World continents.<br />

42 is, as you probably already know, the<br />

answer to the huge algorithm - Earth, its<br />

inhabitants and its many creatures - that<br />

was set up to solve the meaning of Life,<br />

The Universe and Everything in Douglas<br />

Adams' book, the Hitchhiker's Guide to<br />

the Galaxy. It's a shame he never lived to<br />

see the introduction of the concept of<br />

Digital Twins, which in its ultimate form<br />

creates an environment for a deeper<br />

understanding of processes and<br />

consequences in all of the areas in which<br />

it is being adopted. I am not so sure that<br />

we have the intelligence though to unravel<br />

an opaque answer like 42!<br />

It does however underline that people are<br />

the most critical element in any sort of<br />

future planning. The last couple of months<br />

alone have shown how the demographics<br />

of the world are changing. In the UK<br />

political parties and allegiances are being<br />

torn apart by the contradictions of Brexit,<br />

and the ease with which social media can<br />

be used to raise issues, gather adherents<br />

to causes and stage demonstration is<br />

sharply illustrated by protest groups like<br />

Extinction Revolution and other<br />

environmental protagonists.<br />

Future plans, therefore, will have to<br />

consider how the impact of technology,<br />

finite resources and increased urbanisation<br />

will affect people's life and work patterns,<br />

create social upheavals, reduce travel<br />

opportunities - you can probably add a<br />

couple of your own here. If we want to plan<br />

the future, we need to better understand the<br />

role that we will inevitably play in it.<br />

4 May/June 2019

THE ULTIMATE<br />

SOFTWARE FROM<br />

SKETCH TO BIM<br />

Vectorworks Architect is the versatile solution<br />

that will save you time and allow you to sketch,<br />

draw, and model in a fully integrated BIM workflow.<br />

TO LEARN MORE, VISIT VECTORWORKS.NET/UK/ARCHITECT<br />

VILLANOVA ICÔNE | DESIGN BY HAMONIC+MASSON & ASSOCIÉS

News MayJune pg6.qxd 11-Jun-19 9:57 AM Page 1<br />

INDUSTRY news<br />

SMART UPDATES FOR NEW 3D REPO UPDATE<br />

3D Repo has just released<br />

the latest version of its<br />

cloud-based digital construction<br />

platform. Newly added<br />

features include data validation<br />

using Smart Groups,<br />

native Revit file support,<br />

updates to SafetiBase (Health<br />

& Safety Issue Tracker), API<br />

key access, and additional<br />

rendering options.<br />

The latest update has a<br />

strong focus on democratising<br />

otherwise difficult data<br />

operations, along with timesaving<br />

features to increase<br />

overall productivity for all<br />

users of the platform. The<br />

newly added and highly anticipated<br />

Smart Groups feature<br />

is one of the most updates to<br />

the platform in recent times,<br />

giving users a simple way to<br />

validate the data and group<br />

model elements.<br />

"The great thing about this<br />

feature is that it opens up the<br />

data validation process to all<br />

stakeholders regardless of<br />

their knowledge of software or<br />

licensing limitations of other<br />

software" says founder & CEO<br />

of 3D Repo, Jozef Dobos.<br />

3D Repo also now includes<br />

native Revit support, meaning<br />

users can now upload Revit<br />

files directly to the 3D Repo<br />

platform where they can be<br />

managed in an online database<br />

and used in federations<br />

for design coordination. "This<br />

is a great addition to the platform<br />

as it is going to save<br />

users potentially hours of time<br />

when federating models with<br />

each design iteration. Where<br />

previously users would export<br />

to IFC file format before<br />

uploading, now you can simply<br />

upload files directly from<br />

Revit" said Dobos.<br />

3D Repo's SafetiBase feature,<br />

a collaborative way to<br />

share and use health and<br />

Safety information and project<br />

risk data within the model has<br />

also had an update. Key<br />

updates include a full audit<br />

trail of changes for each risk,<br />

additional post mitigation risk<br />

options, ability to add and<br />

track residual risk and support<br />

for multiple markups.<br />

SafetiBase conforms to the<br />

specification for 'collaborative<br />

sharing and use of structured<br />

health and safety information<br />

using BIM' (Publicly Available<br />

Specification PAS 1192-6).<br />

3D Repo now also offers API<br />

Key to its users. Making the<br />

authentication process easier<br />

when integrating custom<br />

workflows or making API calls<br />

from other software. The platform<br />

now comes with additional<br />

rendering options to<br />

enhance model presentation<br />

for better visualisation.<br />

www.3drepo.com<br />

VERIFICATION FOR APPROVED DOCUMENT Q<br />

BSI has launched a new verification<br />

scheme to help<br />

non-manufacturer installers of<br />

windows and doors demonstrate<br />

compliance with<br />

Approved Document Q. This<br />

new scheme provides installers<br />

with independent verification<br />

that they fulfil this aspect of The<br />

Building Regulations by<br />

assessing their organisation's<br />

capability to supply and install<br />

products that meet PAS 24:<br />

Enhanced security performance<br />

requirements for doorsets and<br />

windows in the UK. This is one<br />

of the routes to compliance referenced<br />

within Approved Document<br />

Q for England and Wales<br />

covering security in dwellings.<br />

By assessing an organisation's<br />

capability to provide<br />

compliant products, this verification<br />

scheme enables the<br />

installer to achieve a certificate<br />

in their company name, verified<br />

by BSI that can be handed<br />

to those that require compliance<br />

evidence.<br />

www.bsigroup.com<br />

A BETTER WORKING ENVIRONMENT BY DESIGN<br />

Oasys GSA 10.0 is the latest and 2D entities, e.g. the intersection<br />

of columns with slabs.<br />

release of the powerful<br />

and popular suite for advanced • Imperfection analysis: GSA<br />

structural analysis and design. 10.0 enables the engineer to<br />

GSA provides a comprehensive analyse a model with imperfections<br />

toolset for model creation,<br />

without changing the<br />

analysis, design and results actual model geometry.<br />

visualisation, and is compatible • Design codes: GSA 10.0<br />

with leading BIM solutions used adds support for concrete<br />

by engineers and architects. design to the AASHTO code<br />

The latest release improves and the updated and ASCE 7-<br />

the tools for model creation, 16 seismic code.<br />

enabling engineers to move • Faster slab reinforcement<br />

away from working directly with calculations: A new option to<br />

the analysis model towards calculate reinforcement and to<br />

working with the design model store data in user modules<br />

of the building. Key new features<br />

allows for much faster calcula-<br />

include:<br />

tion and display of results.<br />

• Slab and wall members: The • Multiple instances of GSA:<br />

GSA design layer has for some Opening a new model will<br />

time provided beam and column<br />

automatically open a new GSA<br />

members. The addition of session, so that only views<br />

new slab and wall members and tables associated with a<br />

allows a more-complete definition<br />

single model are displayed in<br />

of the building structure and a single session.<br />

for the interaction between 1D www.oasys-software.com<br />

6<br />

May/June 2019

MODEL<br />

CHECKING<br />

FOR<br />

QUALITY.<br />

Use Solibri Model Checker to guarantee the quality<br />

on your construction projects. As the industry moves<br />

on from clash detection and geometry checks our<br />

solution offers:<br />

• Second Generation Clash Detection<br />

• Model version comparison and reporting<br />

• COBie validation and export<br />

• Instant and visual BIM data mining<br />

• Customisable and user defined rulesets<br />

• Supports collaborative workflows<br />

• And much more...<br />

TRIAL<br />

DOWNLOAD THE FREE TRIAL AT SOLIBRI.COM<br />

AND START SAVING TIME & MONEY RIGHT AWAY.

INDUSTRY news<br />

VECTORWORKS CERTIFIED FOR IFC4 EXPORT<br />

Vectorworks, Inc. has<br />

become the first architectural<br />

software developer to achieve<br />

IFC4 Reference View 1.2 Export<br />

Certification (Architectural Reference<br />

Exchange). The certification<br />

comes from buildingSMART<br />

International, the worldwide<br />

authority driving the transformation<br />

of the built asset economy<br />

through creation and adoption<br />

of open, international standards.<br />

The new IFC4 certification<br />

means Vectorworks officially<br />

meets the export criteria for the<br />

International Organisation for<br />

Standards ISO-16739. This<br />

standard gives users a publicly-defined<br />

and accepted<br />

EPIC GAMES ACQUIRES TWINMOTION<br />

standard to serve as the basis<br />

for contracts.<br />

"The IFC file format gives<br />

focus to the standardised<br />

exchange of data when sharing<br />

information among different<br />

software systems used in the<br />

building industry, said Rubina<br />

Siddiqui, director of product<br />

marketing at Vectorworks. "In<br />

the past, IFC was more<br />

focused on the technical side<br />

of data, making it difficult to<br />

navigate for architects and<br />

designers. The alignment with<br />

familiar and accepted standards<br />

of ISO makes IFC more<br />

relatable for architects."<br />

www.vectorworks.net<br />

Abvent Group has sold Twinmotion,<br />

a leading 3D<br />

immersion software for architects<br />

and designers, to Epic<br />

Games, the creator of the hit<br />

video game Fortnite and<br />

Emmy-award winning Unreal<br />

Engine software.<br />

With the rapid evolution of<br />

real-time visualisation, Abvent<br />

developed Twinmotion to<br />

become one of the world's<br />

leading architectural and urban<br />

planning software solutions,<br />

offering groundbreaking exploration<br />

and 3D immersion technologies<br />

for BIM models. Epic's<br />

global reach will give Twinmotion<br />

the universal exposure that<br />

it needs to grow further.<br />

"Abvent has been a leader in<br />

embracing real-time technology<br />

to help AEC professionals<br />

easily deliver stunningly<br />

detailed, lifelike representations<br />

of their designs using Twinmotion,"<br />

said Marc Petit, General<br />

Manager, Unreal Engine, Epic<br />

Games. "We're thrilled to continue<br />

building this stellar and<br />

intuitive product to make highend<br />

visualisation even more<br />

accessible to the global architecture<br />

community."<br />

www.unrealengine.com/<br />

twinmotion<br />

ISG LASER SCANNING BOOSTS BIM DELIVERY<br />

Global construction services<br />

company ISG is<br />

using the latest 3D modelling<br />

technology to boost its BIM<br />

capabilities. By introducing<br />

Pointfuse laser scanning software,<br />

ISG has speeded workflows<br />

with rapid scan-to-BIM<br />

modelling whilst maintaining<br />

high levels of accuracy.<br />

Traditionally this laser data<br />

processing could take up to<br />

three days to 3D model a single<br />

floor, however, using Pointfuse<br />

ISG has reduced this to a<br />

matter of hours. The use of<br />

Pointfuse has also increased<br />

the range of the point cloud<br />

outputs with applications<br />

including clash detection and<br />

visualisation.<br />

"Scan-to-BIM modelling was<br />

previously seen as undesirable<br />

by the construction industry<br />

due to the time taken to complete<br />

and the risk associated in<br />

doing so," commented Ben<br />

Callan, BIM Coordinator in<br />

ISG's UK Fit Out business.<br />

"However, using Pointfuse we<br />

have further improved our ability<br />

to push out point cloud<br />

data; accelerating analysis and<br />

modelling output and defining<br />

this output with improved tolerances<br />

and levels of detail. This<br />

ultimately enhances our BIM<br />

offering as a business."<br />

ISG had already recognised<br />

the benefits of capturing accurate<br />

site or as-built conditions<br />

using a Faro M70 laser scanner<br />

to capture and analyse<br />

point cloud data to support<br />

BIM delivery and 2D design. In<br />

order to understand the potential<br />

of Pointfuse, ISG benchmarked<br />

the software against<br />

traditional means of modelling<br />

to determine which method<br />

was best for the business.<br />

Using Pointfuse ISG accelerated<br />

its 3D model output,<br />

reducing the time taken to<br />

produce a model from<br />

between 2-3 days to just four<br />

hours per floor. Offering selectable<br />

geometry Pointfuse has<br />

also removed ISG's reliance<br />

on the complete point cloud<br />

for modelling, allowing users<br />

to work with only the data they<br />

require for a specific application,<br />

realising additional time<br />

savings and efficiency gains.<br />

"Using Pointfuse we can create<br />

intelligent 3D mesh models<br />

in a fraction of the time,"<br />

continued Callan. "This accelerated<br />

modelling and reduced<br />

risk of error contributes to a<br />

direct reduction in costs when<br />

compared against traditional<br />

methods of modelling and<br />

point cloud data analysis."<br />

http://pointfuse.com<br />

8<br />

MayJune 2019

CASE study<br />

A National Digital Twin<br />

A dynamic digital twin was created at Cambridge University's Institute for Manufacturing to test<br />

the challenges and issues associated with developing a digital model of infrastructure assets<br />

IfM building, Cambridge University<br />

Bentley Systems recently hosted a<br />

small conference at their Digital<br />

Advancement Academy in London<br />

with the grand title 'Future Infrastructure<br />

Symposium.' It consisted of two contentfilled<br />

days looking at the latest<br />

technological advances in construction,<br />

and hearing predictions from those<br />

involved in planning for the future. The<br />

digitisation of infrastructure assets<br />

obviously played a significant role<br />

throughout the course of the symposium,<br />

covering a wide area of subjects with talks<br />

given by senior members of the teams<br />

delivering projects like HS2.<br />

One of the most interesting<br />

presentations covered the development<br />

of a national digital twin to fulfil the<br />

requirements of a report produced by the<br />

UK National Infrastructure Commission,<br />

entitled 'Data for the Public Good', with<br />

the aim of providing 'high-quality,<br />

standardised data on all our infrastructure<br />

assets, along with the ability to share this<br />

securely, and to enable the UK's<br />

infrastructure to be viewed as an<br />

interdependent dynamic system.'<br />

As you will most definitely be aware by<br />

now, as the term is increasingly being<br />

adopted within a number of hi-tech<br />

industries, a digital twin is a computer<br />

model that mirrors and simulates an asset<br />

or a system of assets and their<br />

surrounding environment - providing and<br />

sharing information about its current<br />

design, state, condition and its history.<br />

Digital twins in whatever field can be used<br />

to gather and organise data about an<br />

asset and its environment and use it to<br />

optimise its performance.<br />

The presentation was given by Ajith<br />

Parlikad, a Ph.D. research fellow at<br />

Cambridge University, the location for the<br />

digital twin pilot demonstrator project,<br />

assisted by Bruce Hutchinson, a senior<br />

consultant at Bentley Systems. Funded by<br />

the Centre for Digital Built Britain, the<br />

project is to develop a dynamic digital<br />

twin of the IfM (Institute for Manufacturing)<br />

and its West Cambridge campus. The aim<br />

is to demonstrate the impact of operating<br />

a digital twin on facilities management<br />

and the wider productivity of a project.<br />

Actually, the name national digital twin is<br />

a bit of a deception. No one is aiming to<br />

create a single digital twin, but a<br />

federation of many twins representing<br />

assets and systems at all levels brought<br />

together to generate the greater picture.<br />

It is hoped the project will demonstrate<br />

the impact of creating a digital modelling<br />

of the site, and the subsequent analysis of<br />

infrastructure on organisational<br />

productivity. It will also provide a means of<br />

integrating city-scale data to optimise<br />

services such as power, waste, and<br />

transport, and evaluating the impact on<br />

wider social and economic outcomes.<br />

Principally, though, by establishing a<br />

'research capability platform' to address<br />

the challenges of implementing digital<br />

technologies in depth, the project will<br />

foster a research community interested in<br />

developing new ideas and applications<br />

for ageing infrastructure systems.<br />

HOW IS IT GOING?<br />

The IfM is working in partnership with a<br />

number of companies operating in this<br />

area, the main one of course being<br />

Bentley Systems, assisted by Redbite,<br />

Topcon and GeoSLAM, with the<br />

development structured along three<br />

interconnected work packages.<br />

WP1 focuses on data development. This<br />

is centered around a 3D geometry model<br />

of the West Cambridge site, comprising a<br />

BIM model of the IfM building with<br />

medium detail and a model of specific<br />

10<br />

May/June 2019

CASE study<br />

The dashboard first view gives a user more comprehensive access<br />

to all the available data. Users can create custom KPIs and<br />

dashboards to give maximum value and assist with decision support<br />

Within the IfM, the Plant room model was created using laser scans<br />

and photogrammetry. Classified objects are integrated within the<br />

AssetWise common data environment<br />

areas created using Bentley's<br />

ContectCapture that need higher levels of<br />

detail Bentley Systems provided the<br />

expertise for the BIM model, whilst the<br />

ContextCapture detailing scans were<br />

captured by GeoSLAM. Topcon with their<br />

drones and vehicle-based scanning<br />

systems provided low-level detail geometry<br />

and photogrammetry of the site.<br />

Redbite is responsible for amassing the<br />

asset information, tagging the most critical<br />

components and recording everything<br />

within a comprehensive asset register -<br />

supported by the deployment and testing<br />

of IoT sensors and devices to monitor and<br />

control the condition and operation of<br />

critical assets and the environment within<br />

the IfM. The trial site is not huge - with<br />

around 50 sensors installed and<br />

approximately 200 sensors tagged - but<br />

sufficient to learn what assets are in situ<br />

and the challenges and issues involved in<br />

collecting, interpreting and using their data.<br />

DATA INTEGRATION<br />

The second stage involves integrating all of<br />

that data from the numerous data sources<br />

and developing applications that analyse it<br />

and link it to the 3D BIM model. Bentley's<br />

AssetWise operational analytics platform<br />

was used to store, analyse and display all<br />

the data as a single reference dataset that<br />

can be accessed and linked live to multiple<br />

external systems. A building management<br />

system was put in place, and the WP<br />

explored the integration of the BMS with<br />

Bentley's AssetWise.<br />

That sounds straightforward enough, but<br />

the aim of the digital twin project is to be<br />

able to access information from any<br />

source, location, device or individual<br />

manufacturer with their own standards and<br />

ways of measuring data and to understand<br />

it, use it and integrate it within the asset in<br />

a vendor-neutral format. Incidentally this<br />

overrides some of the shortfalls in IFC -<br />

becoming, in short, an interoperable,<br />

common data environment (CDE).<br />

WP3, the final stage of the programme,<br />

aims at fulfilling the role of the digital twin<br />

by using the information in it to develop<br />

utilisation and maintenance plans for<br />

equipment within the IfM site - the HVAC<br />

systems, laboratory and other workshop<br />

equipment - to find ways of reducing<br />

energy consumption across the site and to<br />

create a series of augmented reality videos<br />

to assist with the maintenance and<br />

inspection of that equipment.<br />

All of the sensors feed into the cloudbased<br />

BIM model, providing snapshots of<br />

their readings in real-time, signalling their<br />

status using traditional 'traffic light'<br />

warnings, to provide anomaly detection,<br />

signal problems and help develop<br />

maintenance prioritisation tools. This<br />

reduces their cost whilst increasing their<br />

effectiveness.<br />

As Bruce Hutchinson put it, "The<br />

manufacturing industries most suited to<br />

the use of digital twinning could be within<br />

the oil and gas industry and the<br />

construction industry. Oil and gas<br />

companies come with high-value assets<br />

offshore or onshore. If they fail, they have<br />

catastrophic environmental and/or<br />

political implications.<br />

"With assets often in remote or<br />

dangerous locations they rely on remote<br />

devices to broadcast their operational<br />

data which, however, in offshore oil<br />

installations could include various data<br />

sources such as OSI pi, SCADA, OPC<br />

which do not usually communicate with<br />

each other. Creating a 3D representation<br />

of the installation and overlaying the<br />

operational data onto a model of the asset<br />

will assist multiple departments within the<br />

company such as chemistry, drilling,<br />

subsea through to design.<br />

"When overlaying the timeseries data," he<br />

added, "the model staff have the<br />

information they need to make critical<br />

decisions. The chemists would know the<br />

chemical flow through any given section of<br />

pipeline at any point in time and, using the<br />

same model, the design team would have<br />

the information they need to know that if<br />

they changed the piping design, would<br />

that affect the chemical flow?"<br />

JUSTIFYING THE DIGITAL TWIN<br />

So, here we have the principal justification<br />

for the creation of digital twins. It is to<br />

create complete digital copies of a<br />

building, manufacturing process, or chunk<br />

of infrastructure - and to use them to<br />

explore new ideas and processes to<br />

optimise their functions or to improve their<br />

performance. A digital twin is an ideal<br />

vehicle for iterative non-destructive or noninvasive<br />

research into all aspects of an<br />

entity's functions and processes.<br />

www.bentley.com<br />

May/June 2019 11

CASEstudy<br />

Surfacing upgrade<br />

Toppesfield explain the benefits that implementing Re-flow has provided on and offsite for their<br />

surfacing projects<br />

Surfacing roads is as complex an<br />

operation as any other civil<br />

engineering process. Whether it<br />

involves laying down Asphalt on a new<br />

stretch of road, airport runway or<br />

supermarket car park, or merely<br />

replacing a stretch of worn out road in<br />

the countryside, it involves risk, the use<br />

of heavy machinery, and hard work.<br />

It's also subject to pressures from<br />

schedules and deadlines, foul weather,<br />

local traffic issues, timing material<br />

deliveries and the process itself. Small<br />

wonder then that any technological<br />

advances that can mitigate against<br />

these issues are evaluated and, if<br />

proven worthy, taken on board.<br />

A case in point is Toppesfield, the<br />

UK's largest independent surfacing<br />

contractor, which has adopted Reflow's<br />

Site Management solution, a<br />

cloud-based application that informs<br />

field operators, from managers to<br />

labourers, what they should be doing<br />

via their mobile devices, where and<br />

with what, ensuring that everybody has<br />

carried out their instructions after each<br />

particular task is finished.<br />

Re-flow carried out their own survey<br />

of Toppesfield's operation, as they felt<br />

it would provide valuable insights for<br />

other companies wishing to embark on<br />

the same path.<br />

BETTER THAN CURRENT<br />

PRACTICES<br />

Having confirmed that Toppesfield<br />

works across all sectors of the<br />

construction industry, Sam Hennessy,<br />

Business Improvement Manager at<br />

Toppesfield, outlined the challenges<br />

faced by the company. "We lacked<br />

both consistency and availability of<br />

information being delivered to the<br />

office and wanted to make our<br />

reporting easier and more consistent.<br />

We were also looking for a solution<br />

that would be easy for our operatives<br />

to use, provide constant information<br />

and better than current practices."<br />

He said that Re-flow were considered<br />

because they already worked in the<br />

same sector, and they stood out when<br />

compared to others principally<br />

because of the simplicity of the user<br />

interface and its design. "The most<br />

appealing features of Re-flow," Sam<br />

added, "is the ability to record data<br />

when you haven't got a data<br />

connection. We work on remote sites<br />

12<br />

May/June 2019

The First Performance 3D Printer.<br />

Bridging the gap between industrial and desktop 3D printing.<br />

Industrial Reliability + Precision<br />

• Match design dimensions<br />

• Dimensional accuracy of ±0.2mm*<br />

Fastest CAD to Part<br />

• Up to 2x faster than desktop 3D printers**<br />

• Seamless printing workflow<br />

Maximum Innovation + Minimal<br />

Investment<br />

• About ⅓ the first-year cost of ownership<br />

of an entry-level industrial 3D printer<br />

• Accelerate your design process and<br />

reduce risk<br />

To find out how to get better, faster innovation in your<br />

design workflow contact us on 0115 9380 380<br />

or email marketing@artsystems.co.uk<br />

*± 0.2 mm or ± 0.002 mm per mm of travel (whichever is greater). Based on internal testing of selected geometries.<br />

**Compared to popular desktop 3D printers when using the same layer height and infill density settings.<br />

Speed advantage dependent upon object geometry.

CASEstudy<br />

where we don't have a connection so<br />

the forms can be saved and submitted<br />

when we're back online."<br />

Most importantly, Sam explained how<br />

the system was trialled and then<br />

adopted by the company, using<br />

feedback to fine-tune its operation. "The<br />

key is that we could modify the forms for<br />

users in the background without them<br />

knowing that the changes are taking<br />

place, posing questions in a different<br />

format to elicit the required answer.<br />

"After identifying Re-flow as a solution,<br />

we created a select number of forms<br />

which we rolled out to 6/7 users on site,<br />

just last November. We beta tested<br />

those guys who really enjoyed using it<br />

and the information we were getting<br />

back was good, so we tweaked those<br />

forms further, and then in the new year<br />

we rolled it out to the whole team - over<br />

100 devices. We've been using them<br />

ever since, so it was pretty much from<br />

nothing to full blown Re-flow."<br />

Sam added that since implementing<br />

Re-flow, the form compliance has been<br />

amazing: "They come back when we<br />

need them with the information we<br />

want on them, on time. It's great! I<br />

expect Re-flow to save us money<br />

through the information that we get<br />

back. Our defect reporting has<br />

increased by 90%, and we have more<br />

specific questions set for the defects,<br />

to identify small faults before they<br />

become big expensive faults.<br />

"The two things that have impressed<br />

me most about Re-flow, though, are<br />

the support that they've given us,<br />

especially helping to integrate data<br />

into our existing database and that<br />

they've given us a system that<br />

provides complex information in a<br />

really simple way.<br />

"In the future we hope that Re-flow<br />

replaces all of our site-based paper<br />

forms. However, we now realise that<br />

we have underestimated the<br />

capabilities of Re-flow and that it offers<br />

solutions to issues we hadn't<br />

previously identified. We've been really<br />

impressed with Re-flow and have<br />

already recommended it to a couple of<br />

our clients."<br />

HEALTH AND SAFETY<br />

John Turner is Toppesfield's<br />

Compliance Manager. He explained,<br />

from his point of view, that the main<br />

problems were the amount of<br />

paperwork which had to be completed<br />

by the site crews - daily briefings, risk<br />

assessments and method statements.<br />

"We wanted something more user<br />

friendly and which kept all our<br />

paperwork in one place, without site<br />

teams having to carry reams and<br />

reams of paper about.”<br />

"After implementation there was<br />

some apprehension, especially from<br />

some of the older folks, like myself -<br />

not always the best with new IT<br />

equipment - but since we've had them<br />

in use and trialed them, feedback from<br />

even the most sceptical people has<br />

been very positive. Safety tours are<br />

now carried out on a much more<br />

regular basis, and instead of<br />

registering them as last thing of the<br />

month, we can complete site visits and<br />

send them off straight away. Done on<br />

the spot, it’s now done regularly, at a<br />

steadier pace and without rushing - a<br />

big improvement."<br />

FINANCIAL BENEFITS<br />

Mark Salmon is the finance director at<br />

Toppesfield. He explained that<br />

Toppesfield covers the whole country,<br />

on highways, in retail, aviation and<br />

ports - quite some breadth to deal<br />

with. For this reason the flow of<br />

information from sites was also a<br />

critical factor, along with its<br />

consistency.<br />

To improve this, it was decided to<br />

provide technology on site, rather than<br />

having to rely on phone calls or emails<br />

to ensure the same kind of information<br />

is reaching the office every day<br />

detailing what they had done.<br />

Last year, he explained, Toppesfield<br />

had implemented a new ERP system.<br />

"The next step was to tie that in with<br />

site information coming back - but we<br />

soon realised we needed to partner<br />

with an app software company. The<br />

one we chose, Re-flow, has had a big<br />

impact across the whole business. We<br />

ask staff to report near-hits, learn from<br />

potential risks and mitigate them at the<br />

earliest possible opportunity.<br />

"Since implementing Re-flow, our<br />

compliance on reporting defects on<br />

plant and machinery is at its highest<br />

ever levels, and importantly, we now<br />

have clarity around issues submitted,<br />

and which can be tackled straight<br />

away. Overall it has been an<br />

overwhelming success, and we're<br />

already looking at what other areas of<br />

the business we can actually use this<br />

technology for, such as sickness<br />

reporting or scheduling."<br />

THE VIEW ON SITE<br />

Wayne Rust is the Foreman of an<br />

Asphalt gang. He has found Re-flow<br />

really easy to use, with its accessibility<br />

to everyone. "It speeds things up in<br />

the morning and everyone's on par<br />

immediately with what's going on, and<br />

being able to correspond with the<br />

office efficiently to get problems<br />

sorted. Before Re-flow, it seemed to<br />

be just one man doing everything.<br />

Now Re-flow enables everybody to do<br />

their own jobs more effectively.<br />

"We're on top of defects as well, and<br />

if problems do occur there's a 'paper'<br />

trail we can download with proof that<br />

we followed the right reporting<br />

processes. I think it keeps everyone<br />

on their toes."<br />

Charles Twyman, trainee supervisor,<br />

found Re-flow easy to use as well. "It's<br />

easy to manage. I've been doing it for<br />

about 3-4 weeks now and it's been<br />

quite easy to learn, as it has<br />

everything in one place. With the older<br />

system, before we started using Reflow,<br />

there was more paperwork. Now<br />

it's sent straight away, pictures<br />

included, and it takes me half the time<br />

to send everything off."<br />

www.re-flow.co.uk<br />

14<br />

May/June 2019

CASEstudy<br />

From 2D to BIM<br />

A new 'Build to Rent' development at Pontoon Dock on the DLR provides a perfect illustration of<br />

the way processes are involved in a typical BIM project using Vectorworks software throughout<br />

For Assael Architecture, what started<br />

as a humble beginning with two staff<br />

members grew into an awardwinning<br />

practice comprising several teams,<br />

directors, associate directors, and<br />

managers. With over 20 years of expertise<br />

in the design of mixed-use, residential-led<br />

developments in large, urban areas, the<br />

practice primarily works in major cities<br />

throughout the UK and is expanding its<br />

international presence with projects in<br />

Russia, Bahrain, and Germany.<br />

Assael's multi-faceted teams range in size<br />

and scope, and they work on several<br />

projects at the same time - many of them at<br />

different stages of the design process.<br />

"We've become a very versatile practice,"<br />

said Simon Pitt, one of the directors at<br />

Assael. This reputation has led to a variety<br />

of interesting partnerships and projects, for<br />

which the team relies on Vectorworks. One<br />

of these projects - Pontoon Dock - proved<br />

the perfect opportunity for the company to<br />

put its Building Information Modeling (BIM)<br />

planning and coordination into practice.<br />

Pontoon Dock started as land owned by<br />

the Greater London Authority, which<br />

through a bidding process selected Linkcity<br />

(a UK-based Bouygues Construction<br />

company) and Grainger plc to develop a<br />

scheme that could help relieve pressure on<br />

London's housing market. The proposal is<br />

a landmark "Build to Rent" development<br />

comprising three buildings with heights<br />

ranging between 5 and 14 storeys, with 154<br />

private rented apartments and 82<br />

affordable homes, in response to the city's<br />

housing shortage.<br />

Assael's major design challenge was<br />

balancing the build density on the<br />

constrained site, which sits between a<br />

viaduct outside Pontoon Dock DLR<br />

Station and the Thames Barrier Park. "It<br />

was quite a challenge balancing the right<br />

amount of density, being so close to the<br />

viaduct but also sympathetic to the park,<br />

which sits next to the river Thames," said<br />

Pitt. He added that thoroughly going<br />

through each perspective of the project<br />

in every part of the design process was<br />

vital to get that balance right. This was<br />

made simpler through the use of BIM and<br />

the design-oriented BIM capabilities<br />

offered by Vectorworks.<br />

The Assael team set out a project<br />

execution plan scaled to match the size of<br />

each project. "We work with the clients to<br />

make sure they understand the standards<br />

of the program we are working to,"<br />

explained Pitt. "We allocate resources on a<br />

weekly and monthly basis to make sure<br />

that the key project tasks of the program<br />

are being met, while saving time and<br />

unnecessary expenses."<br />

With this in mind, the practice structured<br />

its project workflow to follow a workable<br />

and proven routine:<br />

Assael issued the architectural model<br />

near the end of the week (Friday).<br />

The MEP and structural engineers had<br />

a few days to download the<br />

architectural model and update any<br />

changes to their own models,<br />

uploading their own IFC files the<br />

following week (Tuesday).<br />

Assael downloaded these models,<br />

combined the discipline models<br />

together, and performed clash<br />

detection with Solibri Model Checker.<br />

The resulting federated model was<br />

issued with PDF reports within 24 hours<br />

(Wednesday).<br />

The federated combined digital model<br />

is reviewed at the fortnightly DTM<br />

(design team meeting). All design<br />

coordination prior to the DTM would be<br />

done via a web-based communication<br />

tool called BIMcollab.<br />

This process was repeated in two-week<br />

cycles until the model was finalised. This<br />

systematising of information and model<br />

exchange worked well, and the Pontoon<br />

Dock project was the first of Assael's to<br />

reach BIM Level 2 collaboration.<br />

"We worked very well with the other two<br />

main consultants in Level 2: the<br />

mechanical engineers and the structural<br />

engineers," said Ben Lam, BIM manager<br />

and associate at Assael. "Although it was<br />

difficult at first, it was refined as time went<br />

on. We were all learning this process; the<br />

other consultants have been using Revit<br />

and we've been using Vectorworks. The<br />

level of exchanging Industry Foundation<br />

16<br />

May/June 2019

CASEstudy<br />

Assael BIM coordination drawing<br />

Assael site drawing with flow diagram<br />

Classes (IFC) data has been a challenge<br />

at times, but we managed to fine-tune this<br />

process as the project developed to be as<br />

efficient as possible."<br />

Assael was committed to constant<br />

communication, coordination, and<br />

negotiation to ensure all parties were<br />

presented with a consistent view of the<br />

project status. "We all had to sit around the<br />

table and look at the execution plan, the<br />

timeline, the model, the model exchanges,<br />

and the time for federating the model," said<br />

Lam. He added that these meetings were<br />

crucial, especially since some collaborators<br />

were still working primarily in 2D.<br />

"We definitely spent a lot of time getting<br />

the model right and not just concentrating<br />

on 2D information, even though the<br />

contractors and consultants rely heavily on<br />

2D data," said Lam. Focusing on 3D<br />

modeling was important for the Assael<br />

team to reach their goals and allowed the<br />

firm to share not only the model, but also<br />

2D information more easily.<br />

"Getting the model right and spending<br />

more time at the beginning has really<br />

reaped rewards," said Pitt. "And using<br />

Vectorworks allows us to generate the<br />

2D information a lot quicker than we<br />

could before, especially when we<br />

consider the repeated updating and<br />

refining of the design."<br />

To meet the BIM Level 2 mandate, Assael<br />

had its own workflow adjustments to<br />

absorb. According to Lam, Vectorworks<br />

played a big role in this transition. "It was<br />

quite a natural progression from using<br />

Vectorworks to get into BIM because we<br />

have always used Vectorworks' intelligent<br />

objects like walls, windows, and doors, but<br />

we had never taken advantage of the fact<br />

that they were creating 3D BIM objects<br />

already," he said. "I think our users have<br />

come to realise they're creating BIM<br />

models without having to dramatically<br />

change the way they work. They're starting<br />

to see the benefit of actually generating a<br />

proper model from which they are<br />

generating 2D information and how<br />

effective that can really be."<br />

The software also simplified the number of<br />

steps taken to reach major milestones in<br />

projects. In particular, Renderworks is one<br />

of many features that's proved to be a<br />

game changer. "It's a complete necessity<br />

here because we use rendering a lot for our<br />

elevations," said Lam. "Without<br />

Renderworks, we just would not get the<br />

correct look and feel to our elevations and<br />

the associated information. With many of<br />

our material renders for example, the light<br />

resources and the shadowing are very<br />

important for elevations. So, no matter what<br />

changes we do for the model, the<br />

renderings for the elevations come up just<br />

the way we like them to."<br />

Moving completely to BIM has also<br />

transformed the firm's design process<br />

overall. "In four to five years, projects that<br />

go from initial capacity study through to<br />

planning are now done as BIM models,"<br />

said Lam. "Everyone uses the 3D aspect<br />

much more than they used to; they have<br />

become more proficient in using 3D as part<br />

of the BIM process."<br />

He emphasised the importance of<br />

working completely in 3D. "In the UK, a<br />

massive part of the design process for any<br />

project is gaining planning permission," Pitt<br />

explained. "A vital part of our work is<br />

ensuring that we get the information right to<br />

present to planning committees, planning<br />

authorities, and the general public. When<br />

we moved towards BIM Level 2 using<br />

Vectorworks, we also needed to make sure<br />

the quality of our work didn't drop or was<br />

compromised in any way. The fact that our<br />

existing workflow could be adapted quickly<br />

really helped in the transition."<br />

For Assael Architecture, the switch to BIM<br />

Level 2 compliance has been very effective,<br />

and the results of the Pontoon Dock<br />

project, along with many others, has set the<br />

firm up to continue on the path to a<br />

productive and promising future. "We've<br />

developed our skills in 3D to develop BIM,<br />

and everyone is more proficient now in the<br />

way they use Vectorworks," said Lam. "So,<br />

it's been a natural progression between<br />

what we were using primarily as a 2D tool,<br />

for sections and elevations and plans, to<br />

develop that to 3D information that was<br />

already there but not being utilised."<br />

By fully utilising 3D, creating a BIM<br />

execution plan, and learning how to<br />

successfully conduct an openBIM<br />

workflow process with engineers,<br />

Assael will continue building future<br />

homes - and building its practice - for<br />

many years to come.<br />

www.vectorworks.co.uk<br />

May/June 2019 17

SOFTWAREreview<br />

Powerproject XV<br />

Mark Dixon, Head of Development for Powerproject at Elecosoft, explains the challenges facing project<br />

managers and talks through the latest iteration of Elecosoft's leading project management software -<br />

Powerproject XV<br />

Laptop mock-up<br />

Progress appearance<br />

Elecosoft's Powerproject has been<br />

voted the Construction Computing's<br />

best project management/planning<br />

software for five successive years and has<br />

been chosen by over 90 per cent of the top<br />

100 UK construction contractors. It is widely<br />

used around the world by all sizes of<br />

business from start-ups to multinationals.<br />

The software is designed for simple or<br />

complex tasks from house renovations to<br />

Europe's tallest buildings. For over 30 years,<br />

it has been used for iconic projects such as<br />

The Shard in London, the Victoria and Albert<br />

Museum in London, Hong Kong<br />

International Airport, The Reichstag Dome in<br />

Berlin, Warsaw Metro in Poland and the<br />

Jumeirah Park in Dubai.<br />

Planning efficiently for a construction<br />

project is becoming an increasingly difficult<br />

but essential component for project<br />

managers. Having a robust project<br />

schedule ensures smoother communication<br />

across various team members, managers<br />

and senior executive involved in a project.<br />

However, for a seamless flow of information,<br />

it is imperative that you have confidence in<br />

the project schedules.<br />

As projects become ever more complex,<br />

clients require a trustworthy and reliable<br />

planning and management tool. With a<br />

completely refreshed user interface,<br />

Powerproject XV is designed for the<br />

sophisticated project planner, enabling<br />

them to visualise plans in 4D with realistic<br />

real-time project simulations. Powerproject<br />

XV users can also achieve greater flexibility<br />

and clarity in progress reporting with a new<br />

mobile app, Site Progress Mobile. Here are<br />

some of the highlights:<br />

Schedule Quality Check (SQC): A project<br />

plan can now be assessed using new<br />

automated tests which identify whether it<br />

has been well planned and complies with<br />

industry or corporate standards. You can<br />

build your own thresholds into the<br />

evaluations or follow the included,<br />

recognised, industry metrics that are in line<br />

with the DCMA and CIOB guidelines.<br />

When the SQC is executed, an overall<br />

score is available and a detailed report is<br />

produced, which gives a value to rank the<br />

robustness of your plan as a Red, Amber,<br />

Green and numeric scoring.<br />

The SQC contains a set of industry<br />

standard quality metrics that you can<br />

combine to monitor the quality of a<br />

schedule. For example, you could include a<br />

"Link Logic Metric" which checks that tasks<br />

have at least one incoming and one<br />

outgoing link. You could specify that the test<br />

counts as a pass if 95% or more tasks are<br />

linked and that a fail might equal 85% or<br />

less, with a value between these thresholds<br />

generating a warning.<br />

Talking about the new functionality, Scott<br />

Worthington, National Planner at Wilmot<br />

Dixon says, "The thoroughness, quality and<br />

ultimately the robustness of our project<br />

schedules are things we value highly. Having<br />

a Schedule Quality Check built into<br />

Powerproject will certainly help those who<br />

plan our projects to verify that the right<br />

planning practices have been adopted when<br />

presenting our intended project strategies.<br />

Improved confidence in our planning<br />

schedules will help towards providing<br />

greater time certainty to our customers."<br />

BIM - Build Direction Enhancement: With<br />

this enhancement to Powerproject's 4D<br />

functionality, a 3D element can now be<br />

animated during a time-simulation to give a<br />

more realistic presentation. For instance,<br />

brickwork can be simulated to appear from<br />

the ground up, or piles can be shown<br />

moving downwards.<br />

Baselines: In this version, any new<br />

baselines for local projects are embedded<br />

automatically alongside the live project data<br />

which means that you can email someone a<br />

single file with all the baselines. In addition,<br />

when importing a baseline project, you can<br />

now specify how to map tasks in the<br />

imported file against the ones in the active<br />

project. Chris Aston, a Senior Planner at<br />

Bouygues, says, "A new baseline to be<br />

saved within the actual file is a considerable<br />

leap forward to save the baselines within the<br />

current file and not have them separately."<br />

Progress Appearance: With more display<br />

options on the Bar Chart, you can now<br />

report progress with even more clarity.<br />

18<br />

May/June 2019

SOFTWAREreview<br />

New calendar view<br />

Site progress on mobile phones<br />

The software now has display progress<br />

lines and shading on the Data Zone which<br />

will help to make the report date of each<br />

progress more obvious, particularly when<br />

progress lines are displayed as jagged lines<br />

rather than straight lines.<br />

Talking about the improved reporting<br />

features, Chris Aston, Senior Planner at<br />

Bouygues says, "The ability to use multiple<br />

code libraries and milestone shapes will be<br />

extremely useful. Using these features with<br />

the printing and progress appearance<br />

improvements will allow greater flexibility<br />

and clarity in progress reporting".<br />

Booking data in and out: Booking data in<br />

and out of projects can be a challenge for<br />

remote editing. We have simplified the<br />

whole process. For example:<br />

You can now book out data by selecting<br />

one or more charts or summary groups,<br />

rather than by 'tagging' individual tasks.<br />

Once a summary group(s) has been<br />

booked out, it is now always editable in<br />

the destination project and always readonly<br />

in the master project.<br />

Additionally, a new feature makes it easier<br />

to share part of a plan with a colleague or a<br />

supplier, allowing them to make changes to<br />

the section that you choose. The supplied<br />

changes can then be easily integrated to<br />

the master plan.<br />

Link Chasing: The link properties dialog is<br />

now redesigned to help users understand<br />

the logic arrangement of a plan to visually<br />

highlight and trace dependences<br />

augmenting the existing View Based Path -<br />

to/from and Predecessor/Successor mode.<br />

Scott Worthington of Wilmot Dixon adds,<br />

"Greater control and associated visuals to<br />

forwards and backwards check links will<br />

certainly help our people to better<br />

understand the logical relationships<br />

contained within our schedules."<br />

Calendar view: An improved calendar view to<br />

see the tasks (and/or resources) is now<br />

available on the calendar grid enabling better<br />

communication with all participants in a day,<br />

or a month period for a specific project.<br />

SITE PROGRESS MOBILE<br />

Site managers face the challenge of<br />

carrying bulky ipads or going back and forth<br />

to the office to report live progress of any<br />

ongoing project. This is where the Site<br />

Progress Mobile comes in. A mobile<br />

counterpart of the Powerproject XV<br />

addresses the ground-level issues faced by<br />

workers. The intuitive Site Progress Mobile<br />

system allows teams to report and submit<br />

progress against Powerproject plans<br />

remotely, by using mobile devices. Mobile<br />

devices are easy to carry and are a piece of<br />

technology that even a non-tech person<br />

finds easy to use.<br />

This second generation of the mobile<br />

system focuses on improving user<br />

experience and accommodating new<br />

features, to streamline the progress<br />

reporting operation. For instance:<br />

To remove the subjectiveness of<br />

progressing by percentage, it is now<br />

possible to instead report progress by a<br />

Quantity in the mobile application. Tasks<br />

in Powerproject should have a Task-<br />

Work value assigned to be progressed<br />

in this way.<br />

To improve communication from site to<br />

planner, the photos attached to tasks<br />

can now also be annotated with shapes<br />

and text, as well as having photo<br />

specific notes added.<br />

New tasks can be added remotely (if<br />

allowed) by the Site Progress Mobile<br />

user where new activities are necessary.<br />

These can be named, have a start date<br />

and duration set. They are added into<br />

the Summary where they are created<br />

and have a constraint date set.<br />

Elecosoft customers have warmly<br />

welcomed the product release and see<br />

benefits including:<br />

Better controls over the appearances of<br />

project plans.<br />

Improved confidence in planning<br />

schedules.<br />

Greater flexibility and clarity in progress<br />

reporting.<br />

Powerproject was designed to support the<br />

way construction planners work and has<br />

evolved over many years with input from our<br />

users to meet the requirements of the<br />

industry. Easy-to-use, yet extremely<br />

powerful, it is the software of choice for<br />

thousands of construction professionals<br />

around the world. Now with Powerproject<br />

XV users can have total confidence in the<br />

robustness of their schedules with the<br />

Schedule Quality Check functionality, while<br />

allowing them to communicate effectively<br />

across teams with better control over the<br />

presentation of their plans.<br />

The software appeals to those operating<br />

across the whole spectrum of the<br />

construction sector including pre-build,<br />

modular, fit-out, commercial and residential<br />

builds and infrastructure.<br />

Visit www.elecosoft.com/xv for more<br />

information on Powerproject XV and<br />

www.elecosoft.com/site-progress-newfeatures<br />

for Site Progress Mobile.<br />

May/June 2019 19

SOFTWARE focus<br />

ARCHICAD 23<br />

The latest version of Graphisoft's flagship architectural design application ARCHICAD 23<br />

introduces some interesting tools in Beam and Column design, and Void and Recess creation<br />

How can I improve on the words of<br />

Peter Temesvari, Graphisoft's<br />

Director of Product Management<br />

when he describes the driving force behind<br />

the latest vern of the company's flagship<br />

BIM software solution ARCHICAD 23?<br />

"Everyday tasks such as firing up your<br />

software and switching between projects or<br />

views in a specific project may end up<br />

being the very roadblocks to achieving the<br />

flow, which is the ideal state for architectural<br />

design. We removed these roadblocks,<br />

putting the architect more firmly in the<br />

driver's seat, with the software responding<br />

to the way architects think and work.<br />

ARCHICAD 23's increased responsiveness<br />

is truly remarkable!"<br />

The design tools available to architects<br />

today are capable of creating pretty much<br />

any conceivable form, shape or effect in a<br />

building. The emphasis now is on providing<br />

an environment that makes it easier to use<br />

those tools, improving the performance on<br />

software startup, file opening, working in<br />

multi-project environments and switching<br />

between different views of a BIM project.<br />

Enhancing and simplifying the way people<br />

work gives them more freedom to<br />

concentrate on their designs.<br />

One design tool was open for<br />

improvement, though, the tool that<br />

facilitates the creation of openings in a wall<br />

or façade of a structure. That has been<br />

addressed in the new version of the<br />

software. The latest version of ARCHICAD<br />

also introduces a couple of new<br />

engineering modules, Column and Beam<br />

tools that increase modeling accuracy, and<br />

interoperability with engineering disciplines.<br />

WHAT'S NEW IN ARCHICAD 23?<br />

The recent launch in Las Vegas outlined the<br />

new features in ARCHICAD 23, amongst<br />

them a series of performance<br />

enhancements which have been developed<br />

to provide an uninterrupted flow in an<br />

architect's workflow, starting from launching<br />

the software, to accessing project data and<br />

navigating one's way through the Building<br />

Information Model. This has been achieved<br />

through a combination of raw performance<br />

optimisation, streamlined workflows and<br />

reduced file sizes, an example of the latter<br />

provided by the update Solibri integration.<br />

Mention was also made of the growing<br />

importance of Modular construction and<br />

off-site fabrication, currently exercising the<br />

minds of all developers of architectural<br />

design software - and which, off course, is<br />

fully dependent on BIM technology. We look<br />

forward to seeing further evidence of this in<br />

Graphisoft's future developments.<br />

COLUMN AND BEAM TOOLS<br />

The structural engineering features in<br />

ARCHICAD 23 have been considerably<br />

enhanced, particularly for the Column and<br />

Beam tools, which enable more detailed<br />

modelling of connections, the ability to<br />

create curved roofs and windows (tastefully<br />

depicted as Gothic windows in Graphisoft's<br />

launch presentation), and the ability to<br />

produce quantity estimations for reinforced<br />

concrete, complex steel, timber, and<br />

composite beams and columns, allowing<br />

architects to model faster and create<br />

accurate construction details.<br />

In particular, new tools allow beam<br />

connections to be broken down into<br />

individual segments, and the shape of each<br />

to be modified within a single element to<br />

provide a reshaped and unique beam<br />

connection, the same set of tools allowing<br />

rapid creation of fully parametric multifaceted<br />

and tapered segments in beams.<br />

ARCHICAD 23 also makes it quicker and<br />

easier to create complex columns and<br />

curved, haunched (beams with crosssections<br />

thicker at the supports than in the<br />

middle of the span) and castellated beams<br />

meeting all graphic and representation<br />

standards. Beams and columns can now<br />

be displayed using various projected and<br />

symbolic views and cover fills.<br />

VOIDS, NICHES, AND RECESSES<br />

A considerable amount of time can be<br />

saved using ARCHICAD 23's new Opening<br />

tool, which can be used to model and<br />

coordinate project design voids, recesses<br />

and niches, creating everything from<br />

vertical lift shafts through aligned openings<br />

20<br />

May/June 2019

SOFTWARE focus<br />

on each slab, to multiple wall openings for<br />

the installation of MEP systems. Openings<br />

can be any shape - horizontal, circle, etc.-<br />

and inserted as horizontal, vertical or<br />

slanted openings across elements, element<br />

groups or even across storeys. They can<br />

also be dimensioned, labelled and<br />

scheduled for use in 2D drawings and<br />

other documentation.<br />

To give a couple of examples, the mass<br />

modelling of an elevator shaft can be used<br />

to rapidly create openings in each slab<br />

through which it will pass, the properties of<br />

which are established through the<br />

Openings dialogue box.<br />

Alternatively, multiple openings can be<br />

created in one go to route MEP elements<br />

though buildings comprising load-bearing<br />

walls and other structures. You need to do<br />

this if you are installing a system of central<br />

heating pipes in a building, where you<br />

would use clash detection to pinpoint the<br />

location of each pipe as it meets a wall. The<br />

location and geometry of each required<br />

opening is then established based on the<br />

diameter of the pipe, adding in any<br />

necessity clearances.<br />

Besides placement on the 3D model,<br />

every opening is documented on floorplans<br />

with the appropriate 2D symbols.<br />

Openings, niches and recesses are<br />

created using open IFC standards -<br />

essential for sharing project information<br />

with architects, engineers and consultants<br />

engineers and, of course, MEP engineers.<br />

RENEWED SOLIBRI CONNECTION<br />

Solibri has been associated with Graphisoft<br />

for a long time. The popular application is<br />

used to check the integrity of a design and<br />

the constructability of the 3D model,<br />

throughout all of the stages of the building<br />

process. Although the software includes an<br />

IFC Optimiser which allows users to reduce<br />

large IFC file sizes for quicker and easier<br />

distribution and viewing, ARCHICAD 23<br />

now includes an updated add-on which<br />

automatically detects and sends only those<br />

elements that are changed in the<br />

ARCHICAD model, resulting in faster<br />

round-trip collaboration.<br />

INTRODUCING DROFUS<br />

dRofus is a unique planning, data<br />

management and BIM collaboration tool. It<br />

provides comprehensive workflow support<br />