Open Floating Tenon Joinery - gerald@eberhardt.bz

Open Floating Tenon Joinery - gerald@eberhardt.bz

Open Floating Tenon Joinery - gerald@eberhardt.bz

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

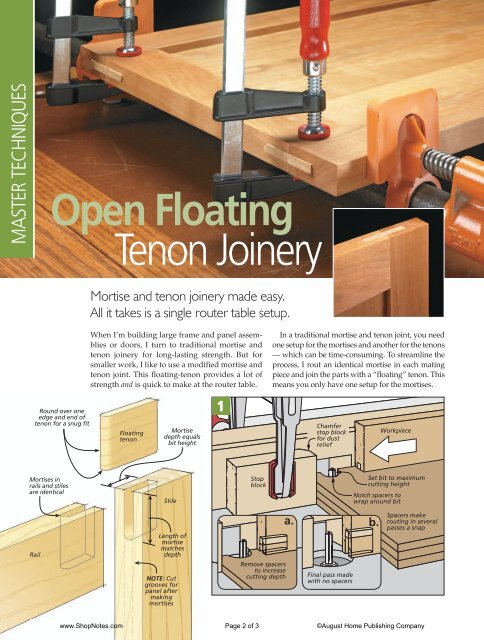

MASTER TECHNIQUES<br />

<strong>Open</strong> <strong>Floating</strong><br />

<strong>Tenon</strong> <strong>Joinery</strong><br />

Mortise and tenon joinery made easy.<br />

All it takes is a single router table setup.<br />

Round over one<br />

edge and end of<br />

tenon for a snug fit<br />

When I’m building large frame and panel assemblies<br />

or doors, I turn to traditional mortise and<br />

tenon joinery for long-lasting strength. But for<br />

smaller work, I like to use a modified mortise and<br />

tenon joint. This floating-tenon provides a lot of<br />

strength and is quick to make at the router table.<br />

<strong>Floating</strong><br />

tenon<br />

Mortise<br />

depth equals<br />

bit height<br />

1<br />

In a traditional mortise and tenon joint, you need<br />

one setup for the mortises and another for the tenons<br />

— which can be time-consuming. To streamline the<br />

process, I rout an identical mortise in each mating<br />

piece and join the parts with a “floating” tenon. This<br />

means you only have one setup for the mortises.<br />

Chamfer<br />

stop block<br />

for dust<br />

relief<br />

Workpiece<br />

Mortises in<br />

rails and stiles<br />

are identical<br />

Stile<br />

Stop<br />

block<br />

Set bit to maximum<br />

cutting height<br />

Notch spacers to<br />

wrap around bit<br />

Rail<br />

Length of<br />

mortise<br />

matches<br />

depth<br />

NOTE: Cut<br />

grooves for<br />

panel after<br />

making<br />

mortises<br />

Remove spacers<br />

to increase<br />

cutting depth<br />

a. b.<br />

Final pass made<br />

with no spacers<br />

Spacers make<br />

routing in several<br />

passes a snap<br />

www.ShopNotes.com Page 2 of 3 ©August Home Publishing Company

ROUTING MORTISES<br />

With an idea of how the joint works, you’re ready to<br />

get set up and start routing. All you need is a regular<br />

1 ⁄ 4"-dia. straight bit (for 3 ⁄ 4"-thick stock).<br />

SETTING UP. Figure 1 shows a good overview of the<br />

router table setup. But details are left to point out.<br />

First, the bit needs to be centered on the workpiece.<br />

This way, the mating pieces will be flush.<br />

Take a look at the box below to see how I did this.<br />

Next, you can set the bit height. For the largest (and<br />

strongest) joint, set the bit to its full cutting length.<br />

SPACERS. But making a full-depth cut like this puts<br />

a lot of stress on the bit and router motor. So I limit<br />

each cut to 1 ⁄ 4" deep and make multiple passes.<br />

The problem here is having to reach under the<br />

table to adjust the height of the router. This is timeconsuming<br />

and can lead to a “stepped” mortise<br />

where the sides aren’t even. Instead, I rely on a set<br />

of 1 ⁄ 4" hardboard spacers. You increase the depth of<br />

cut simply by removing a spacer (Figure 1a).<br />

STOP BLOCK. Next, clamp a stop block to the router<br />

table fence. This way you’ll get identical mortises<br />

in every part. To get the strongest joint, set the stop<br />

block to rout a mortise that matches the bit height.<br />

START ROUTING. Now you can turn on the router and<br />

start making mortises. All the parts are routed the<br />

same way, so you can do this assembly-line style.<br />

FLOATING TENONS<br />

With all the mortises routed, you can move on to<br />

the floating tenons. Using contrasting wood will<br />

“show-off” the tenon (like in the main photo).<br />

SIZING TENON STOCK. To make it easier to work on the<br />

tenons, I do most of the shaping on an oversize<br />

blank. It’s sized for a slip fit in the mortises to make<br />

Centering the Router Bit<br />

Your goal in making a frame and panel assembly<br />

is to have the mating parts fit flush. In order to do<br />

that, the router bit needs to be accurately centered<br />

on the workpiece. Here’s an easy, no-measure way.<br />

Start by “eyeballing” the bit as close to the<br />

center of a short test piece as possible and a hair<br />

toward the outside edge, like you see in Figure 1.<br />

Now, make a pass, flip the workpiece end for end,<br />

and make a second pass (Figure 2). This creates a<br />

groove that’s slightly wider than the bit.<br />

To center the bit, gently nudge the fence closer<br />

to the bit and make a set of passes on a new test<br />

piece. It may take a few tries. You’ll know the<br />

router bit is dead center when it doesn’t remove<br />

any additional material on the second pass.<br />

2 3<br />

Backer<br />

prevents<br />

chipout<br />

!/8"<br />

roundover<br />

bit<br />

Fence<br />

SECOND: Round<br />

over one end<br />

<strong>Floating</strong> tenon<br />

blank<br />

FIRST: Round<br />

over one long<br />

edge of blank<br />

Flip workpiece<br />

over for<br />

second pass<br />

FIRST: Adjust fence<br />

so bit is just off center<br />

to workpiece<br />

a.<br />

NOTE: Bit<br />

should be<br />

a “hair” to<br />

outside to<br />

prevent<br />

backrouting<br />

<strong>Floating</strong><br />

tenon blank<br />

assembly easier. I also cut it extra wide so I can trim<br />

the tenons flush after the frame is glued up.<br />

Making the tenons involves a little “two-step”<br />

between the router table and table saw. After rounding<br />

over one long edge, you’ll round over one end of<br />

the tenon blank, as in Figure 2. This way the tenon<br />

will seat tightly in the mortise. Then cut the tenons<br />

to length at the table saw. I clamped a stop block to<br />

the rip fence to size them identically (Figure 3).<br />

PANEL GROOVE. Now that the joinery is complete, you<br />

can cut the grooves to hold a panel, if necessary.<br />

ASSEMBLY. Finally, to assemble the frame, clamp it<br />

up like you see in the main photo. A pipe clamp<br />

pulls the joint together and a second clamp keeps<br />

it aligned. When the clamps come off, you can trim<br />

the tenons flush with a chisel and sandpaper.<br />

1 2<br />

a. a.<br />

Clamp stop<br />

block to<br />

rip fence<br />

THIRD:<br />

Cut tenon<br />

to length<br />

NOTE: Repeat<br />

steps until bit<br />

is centered<br />

SECOND:<br />

Rout one pass,<br />

THIRD: flip workpiece, and<br />

Adjust fence rout another pass<br />

toward bit and<br />

rout two passes<br />

with new test piece<br />

www.ShopNotes.com Page 3 of 3 ©August Home Publishing Company