MEMS pressure sensors are compact, highly sensitive devices used for pressure measurement in automotive, aerospace, medical, and environmental applications.

MEMS Pressure Sensors: Revolutionizing Sensing Technologies

Introduction

Micro-Electro-Mechanical Systems (MEMS) pressure sensors have gained immense popularity in recent years due to their small size, high sensitivity, and low power consumption. These sensors combine the advantages of mechanical and electrical systems, making them ideal for a wide range of applications, from automotive and aerospace industries to medical devices and environmental monitoring. In this article, we explore the working principle of MEMS pressure sensors, their types, and their various applications.

Working Principle of MEMS Pressure Sensors

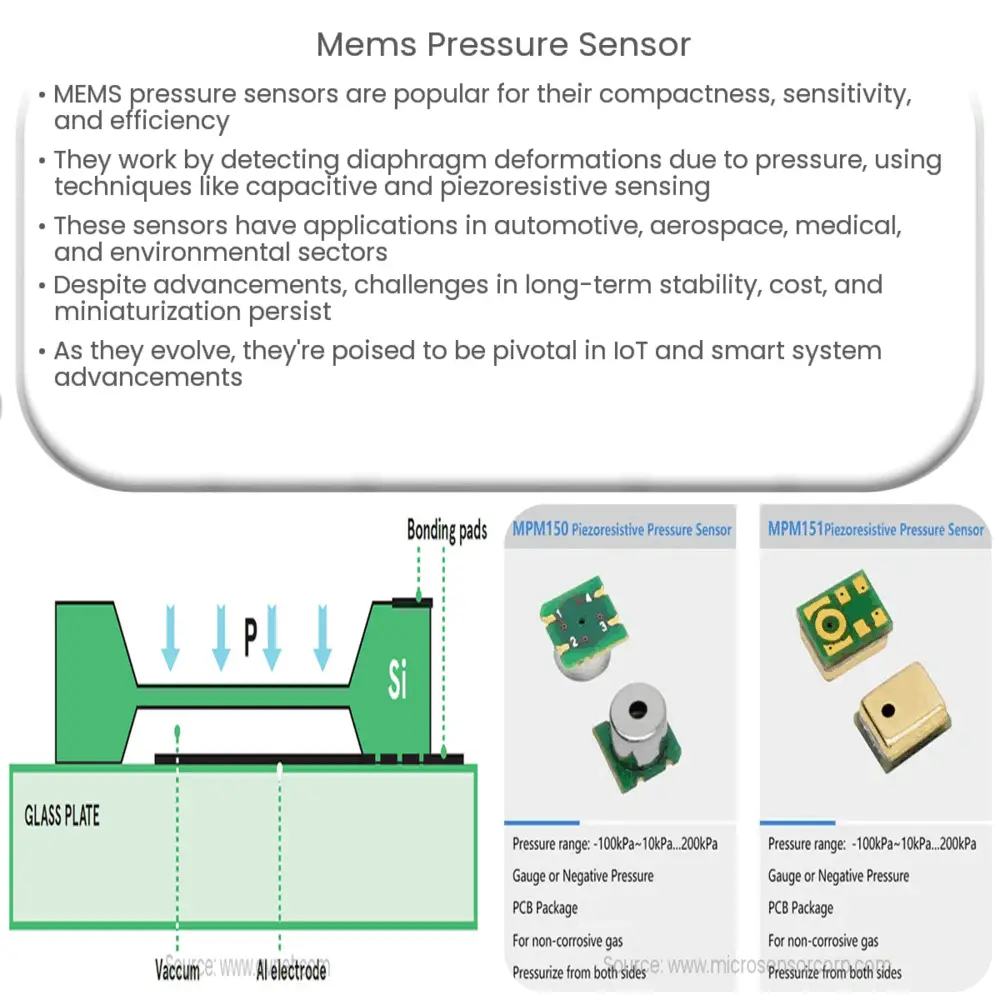

MEMS pressure sensors measure pressure by detecting the deformation of a diaphragm, which is a thin, flexible structure made from materials like silicon or polymers. When subjected to pressure, the diaphragm deforms, causing a change in its electrical properties. This change is detected by the sensor’s electronic circuitry, which translates the deformation into an electrical signal proportional to the applied pressure.

There are various techniques for measuring diaphragm deformation, including capacitive, piezoresistive, and piezoelectric sensing. Capacitive sensing relies on the change in capacitance between two parallel plates as the diaphragm deforms. Piezoresistive sensing uses semiconductor materials whose resistance changes under mechanical stress, and piezoelectric sensing involves the generation of an electrical charge when a material is deformed.

Types of MEMS Pressure Sensors

MEMS pressure sensors are classified into three main types based on the pressure range they can measure:

- Absolute Pressure Sensors: These sensors measure pressure relative to a vacuum, making them ideal for applications where an accurate reference to atmospheric pressure is required, such as barometric pressure measurement and leak detection.

- Gauge Pressure Sensors: Gauge pressure sensors measure pressure relative to atmospheric pressure. They are widely used in industrial applications, such as monitoring fluid levels in tanks or measuring pressure in pipes.

- Differential Pressure Sensors: Differential pressure sensors measure the difference between two pressure points. They are commonly used in applications like air flow measurement in HVAC systems and pressure drop monitoring across filters.

Applications of MEMS Pressure Sensors

MEMS pressure sensors have found their way into numerous industries and applications due to their compact size, high sensitivity, and low power consumption. Some notable applications include:

- Automotive: MEMS pressure sensors are used for monitoring tire pressure, fuel injection systems, and engine management.

- Aerospace: In aerospace, these sensors are utilized for altitude measurements, cabin pressure monitoring, and engine control systems.

- Medical: MEMS pressure sensors are employed in various medical devices, such as blood pressure monitors, respiratory devices, and intracranial pressure monitoring systems.

- Environmental Monitoring: These sensors are used for air quality monitoring, water level measurement, and weather stations.

With continued advancements in MEMS technology, we can expect to see even more innovative applications of MEMS pressure sensors in the future.

Advancements in MEMS Pressure Sensor Technology

As MEMS technology evolves, pressure sensors are becoming increasingly sophisticated, enabling improved performance and new applications. Some recent advancements include:

- High-temperature operation: Researchers are developing MEMS pressure sensors capable of operating at high temperatures, which is crucial for applications in the automotive and aerospace industries, such as exhaust gas monitoring and jet engine control.

- Enhanced sensitivity and resolution: Advances in materials and fabrication techniques have led to the development of MEMS pressure sensors with better sensitivity and resolution, allowing for more accurate and reliable measurements in various applications.

- Wireless and energy harvesting capabilities: The integration of wireless communication and energy harvesting technologies enables the development of self-powered, wireless MEMS pressure sensors, which can be used in remote monitoring applications or in areas where wired connections are not feasible.

Challenges and Future Outlook

Despite the numerous advantages and advancements of MEMS pressure sensors, some challenges still need to be addressed to further enhance their performance and broaden their application scope:

- Long-term stability and reliability: Ensuring the long-term stability and reliability of MEMS pressure sensors, especially in harsh environments, remains a challenge. Researchers are working on developing new materials and packaging techniques to improve sensor durability and lifespan.

- Cost reduction: Reducing the cost of MEMS pressure sensors is essential for their widespread adoption in various industries. This can be achieved by developing cost-effective fabrication techniques and utilizing less expensive materials.

- Miniaturization and integration: Further miniaturization and integration of MEMS pressure sensors with other electronic components and systems will open up new application possibilities and make them even more versatile and efficient.

As technology progresses, we can expect MEMS pressure sensors to overcome these challenges and become an even more integral part of numerous applications across various industries.

Conclusion

MEMS pressure sensors have revolutionized sensing technologies with their small size, high sensitivity, and low power consumption. As the technology advances, these sensors are becoming more sophisticated and finding new applications in diverse industries, such as automotive, aerospace, medical, and environmental monitoring. By addressing the challenges in long-term stability, cost reduction, and further miniaturization, MEMS pressure sensors will continue to play a critical role in the development of smart systems and the realization of the Internet of Things (IoT) in the coming years.