Abstract

The effect of cold rolling deformation on the microstructure and mechanical properties of the spray-formed plus extruded Al–9.8Zn–2.3Mg–1.7Cu alloy is investigated. The results indicate that the percentage of sub-grain in the samples induced cold rolling deformation (solution + cold rolling + aging) increased from 33 to 66%, while the average grain size decreased from 4.76 to 4.37 μm, as compared to the solution-aging treated samples. In addition, the precipitates are finer and more dispersive in the cold rolling deformation treated samples. The dispersed precipitates restrict the dislocation movement and improve the uniformity of dislocation distribution. Furthermore, compared to the solution-aging treatment, the cold rolling deformation makes the tensile strength, yield strength, and elongation of the samples reach a new high of 709 MPa, 683 MPa, and 13.2%, respectively. Fine grain strengthening, dislocation strengthening, and precipitation strengthening are the primary strengthening mechanisms in the alloy.

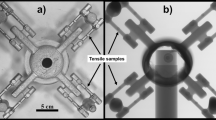

Graphical abstract

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also form part of an ongoing study.

References

Y. Wang, R.Z. Wu, N. Turakhodjaev, M.D. Liu, Microstructural evolution, precipitation behavior and mechanical properties of a novel Al–Zn–Mg–Cu–Li–Sc–Zr alloy. J. Mater. Res. 36(3), 740–750 (2021)

Y.C. Wang, X.D. Wu, Y. Lu, M.X. Guo, L.F. Cao, Aging precipitation behavior and properties of Al–Zn–Mg–Cu–Zr–Er alloy at different quenching rates. Trans. Nonferrous Met. Soc. China 32(4), 1070–1082 (2022)

Q.S. Zhou, C. Li, T.L. Wang, X.J. Xu, Y.T. Luo, Effect of various multi-stage solution treatments on the microstructure and properties of cold-extruded Al–9.74Zn–2.59Mg–0.94Cu–0.2Zr–0.83Ti alloy. J. Mater. Res. 37(21), 3731–3742 (2022)

L. Li, L.J. Wei, Y.J. Xu, L. Mao, S.J. Wu, Study on the optimizing mechanisms of superior comprehensive properties of a hot spray formed Al–Zn–Mg–Cu alloy. Mater. Sci. Eng. A 742, 102–108 (2019)

R.M. Su, Y.D. Qu, J.H. You, Study on a new retrogression and re-aging treatment of spray formed Al–Zn–Mg–Cu alloy. J. Mater. Res. 31(5), 573–579 (2016)

Z.L. Ning, S. Guo, M.X. Zhang, F.Y. Cao, Y.D. Jia, J.F. Sun, Characterization of the secondary phases in spray formed Al–Zn–Mg–Cu–Sc–Zr alloy during hot compression. J. Mater. Res. 31(16), 2465–2472 (2016)

L.Q. Xie, Q. Lei, M.P. Wang, X.F. Sheng, Z. Li, Effects of aging mechanisms on the exfoliation corrosion behavior of a spray deposited Al–Zn–Mg–Cu–Zr aluminum alloy. J. Mater. Res. 32(6), 1105–1117 (2017)

Z.G. Zhang, X.W. Ma, C.S. Zhang, G.N. Chu, Z.J. Meng, G.Q. Zhao, L. Chen, Effect of stress-aging treatment on the mechanical and corrosion properties of Al−Zn−Mg−Cu alloy. Mater. Sci. Eng. A 838, 142791 (2022)

R. Bakhshi, M.H. Farshidi, S.A. Sajjadi, Strengthening of aluminum alloy 7005 through imposition of severe plastic deformation supplemented by different ageing treatments. Trans. Nonferrous Met. Soc. China 31(10), 2909–2921 (2021)

W.T. Huo, J.T. Shi, L.G. Hou, J.S. Zhang, An improved thermo-mechanical treatment of high-strength Al–Zn–Mg–Cu alloy for effective grain refinement and ductility modification. J. Mater. Process. Tech. 239, 303–314 (2017)

H.Z. Li, S.C. Yao, X.P. Liang, Y.H. Chen, C. Liu, L. Huang, Grain boundary pre-precipitation and its contribution to enhancement of corrosion resistance of Al–Zn–Mg alloy. Trans. Nonferrous Met. Soc. China 26(10), 2523–2531 (2016)

Q. Sun, S. Yu, H. Wang, H.J. Ma, H.H. Li, Z.L. Hu, Experimental and simulation study for the influence of thermal pre-deformation on subsequent aging precipitation kinetics of Al–Zn–Mg–Cu alloy. Materials 15(13), 4634 (2022)

J.R. Zuo, L.G. Hou, J.T. Shi, H. Cui, L.Z. Zhuang, J.S. Zhuan, The mechanism of grain refinement and plasticity enhancement by an improved thermomechanical treatment of 7055 Al alloy. Mat. Sci. Eng. A 702, 42–52 (2017)

H.X. Zhu, P.P. Ma, C.H. Liu, J. He, J.S. Yang, L.H. Chen, L.P. Huang, L.H. Zhan, Effect of cryogenic pre-deformation on the stress relaxation response and mechanical/corrosion properties in Al–Zn–Mg–Cu alloy. J. Mater. Res. Tech. 20, 3471–3484 (2022)

H. Li, P. Chen, Z.X. Wang, F. Zhu, R.G. Song, Z.Q. Zheng, Tensile properties, microstructures and fracture behaviors of an Al–Zn–Mg–Cu alloy during ageing after solution treating and cold-rolling. Mater. Sci. Eng. A 742, 798–812 (2019)

M.H. Zhang, C.B. Li, Y. Zhang, S.D. Liu, J.Y. Jiang, J.G. Tian, L.Y. Ye, X.M. Zhang, Effect of hot deformation on microstructure and quenching-induced precipitation behavior of Al–Zn–Mg–Cu alloy. Mater. Character. 172, 110861 (2021)

M.A. Khan, Y.M. Wang, M. Hamza, G. Yasin, M. Tabish, C.S. Feng, W.Q. Khan, T. Ahmad, W.B. Liao, M.A. Afifi, Precipitation behaviour in an Al–Zn–Mg–Cu alloy subjected to high strain rate compression tests. Mater. Character. 180, 111398 (2021)

L. Chen, Y.Z. Hou, Z.G. Li, G.Q. Zhao, C.S. Zhang, Enhancing mechanical properties and corrosion resistance of a high strength 7A99 Al alloy by introducing pre-rolling in solution and aging treatments. J. Alloy. Compd. 898, 162972 (2022)

D. Wang, S.Q. Huang, Y.Q. Yi, H.L. He, C. Li, Effects of cryogenic deformation on the microstructure and mechanical properties of high-strength aluminum alloys. Mater. Character. 187, 111831 (2022)

Z.P. Wang, H.Y. Xiao, W. Chen, Y.G. Li, J.W. Geng, X.F. Li, P.K. Xia, M.L. Wang, D. Chen, H.W. Wang, New insight into precipitation of Al3Zr and correlative effect on recrystallization behavior in a rapidly-solidified Al–Zn–Mg–Cu–Zr alloy. Mater. Character. 191, 112142 (2022)

A. Deschamps, F. De Geuser, Z. Horita, S. Lee, G. Renou, Precipitation kinetics in a severely plastically deformed 7075 aluminium alloy. Acta mater. 66, 105–117 (2014)

B.S. Han, L.J. Wei, Y.J. Xu, X.G. Ma, Y.F. Liu, H.L. Hou, Effect of pre-deformation on microstructure and mechanical properties of ultra-high strength Al–Zn–Mg–Cu alloy after ageing treatment. Acta Metallurg. Sinic. 56(07), 1007–1014 (2020)

S.S. Wang, J.T. Jiang, G.H. Fan, A.M. Panindre, G.S. Frankel, L. Zhen, Accelerated precipitation and growth of phases in an Al–Zn–Mg–Cu alloy processed by surface abrasion. Acta Mater. 131, 233–245 (2017)

Z.G. Yuan, Z.G. Chen, H.J. Li, J.K. Ren, J.L. He, C.H. Lu, Mechanism of novel thermomechanical treatment on microstructure and comprehensive properties of Al–Zn–Mg–Cu alloy. Trans. Nonferrous Met. Soc. China 31(02), 280–288 (2021)

Y. Li, Y. Wang, B. Lu, W. Yu, H.Y. Wang, G.M. Xu, Z.D. Wang, Effect of Cu content and Zn/Mg ratio on microstructure and mechanical properties of Al–Zn–Mg–Cu alloys. J. Mater. Res. Tech. 19, 3451–3460 (2022)

Z.P. Wan, Q.P. Pu, Y.G. Li, P.K. Xia, J.W. Geng, X.F. Li, M.L. Wang, D. Chen, H.W. Wang, Microstructures and mechanical properties of Al–Zn–Mg–Cu alloy with the combined addition of Ti and Zr. J. Mater. Res. Tech. 22, 747–761 (2023)

L. Luo, B.H. Yang, X.R. Yang, W.W. Yan, C. Gan, X.Y. Liu, Effects of different cooling conditions on microstructure and precipitation behavior of fine-grained Al–Zn–Mg–Cu alloy friction stir welding joint. J. Mater. Res. Tech. 24, 4534–4550 (2023)

M.H. Shaeri, M. Shaeri, M. Ebrahimi, M.T. Ssalehi, S.H. Seyyedein, Effect of ECAP temperature on microstructure and mechanical properties of Al–Zn–Mg–Cu alloy. Progress Nat. Sci. Mater. Int. 26(2), 182–191 (2016)

A. Ditta, L.J. Wei, Y.J. Xu, S.J. Wu, Microstructural characteristics and properties of spray formed Zn-rich Al–Zn–Mg–Cu alloy under various aging conditions. Mater. Character. 161, 110133 (2020)

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China Projects (No. 52271177), and the Science and Technology Innovation Leaders Projects in Hunan Province, China (No. 2021RC4036).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare no conflicts of interest associated with this work.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fan, C., Li, Y., Wu, Q. et al. Effect of cold rolling deformation on the microstructure and mechanical properties of spray-formed Al–Zn–Mg–Cu alloy. Journal of Materials Research 39, 471–479 (2024). https://doi.org/10.1557/s43578-023-01242-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-023-01242-z